Maintenance Tips for Elk Grove Asphalt Pavements

Introduction

Maintaining quality road surfaces is crucial for any community, and when it comes to Elk Grove Asphalt Pavements, proper care can make the difference between long-term durability and costly repairs down the road. In this guide, we delve into practical maintenance tips that are not only effective but also tailored for the specific conditions in Elk Grove. Whether you’re a facility manager, a local government official, or a homeowner with an interest in quality pavement upkeep, understanding the ins and outs of asphalt maintenance is key. Have the Best information about paving companies in Elk Grove.

Asphalt pavements are subject to daily wear and tear. Heavy traffic, fluctuating temperatures, and the natural aging process all contribute to deterioration over time. Without timely and appropriate maintenance, small issues such as minor cracks or potholes can quickly develop into severe problems. Fortunately, a strategic approach to maintenance can prevent these issues from escalating. By conducting routine inspections and implementing preventative measures, you can extend the lifespan of Elk Grove Asphalt Pavements while saving on expensive repair costs later.

In the first part of our discussion, we will explore why regular maintenance is essential. Not only does consistent upkeep enhance the safety of road users, but it also improves the overall aesthetic appeal of public infrastructure. Additionally, well-maintained pavements contribute to better water drainage and reduce the risk of accidents. This proactive approach also plays a significant role in environmental sustainability, as it often minimizes the need for full-scale resurfacing projects that consume more resources.

One of the most important aspects to note is that maintenance is an ongoing process. It’s not just about fixing problems when they arise but about creating a schedule that includes regular inspections, cleaning, and minor repairs. This proactive method is particularly vital for Elk Grove Asphalt Pavements, which experience unique environmental challenges such as seasonal rains and temperature extremes. In practice, maintenance plans should include detailed schedules for inspections and repairs, clear checklists for assessing pavement conditions, and an established timeline for addressing issues as soon as they are detected.

Moreover, integrating advanced repair techniques with routine maintenance not only prolongs the life of the pavement but also enhances safety for everyone using the roads. The benefits are multi-fold: reduced long-term costs, improved traffic flow, and a lower incidence of accidents. It’s essential to use high-quality materials and reliable equipment, which further underscores the importance of planning and budgeting for these projects. You might be surprised to learn that a well-planned maintenance routine can significantly lower overall expenses compared to emergency repairs.

Transitioning from the overview, the next sections of our guide provide a deeper look into the specifics of Elk Grove Asphalt Pavements. We discuss their composition, the environmental factors affecting them, and the most effective strategies for routine and preventative maintenance. Along the way, we’ll introduce advanced repair techniques and outline the essential tools and materials needed for any asphalt maintenance project.

By the end of this article, you’ll have a comprehensive understanding of how to care for Elk Grove Asphalt Pavements in a way that is both economically and environmentally sustainable. The insights shared here are grounded in industry best practices, backed by years of experience, and designed to empower you with the knowledge to make informed decisions. So let’s dive in and explore the world of asphalt pavement maintenance, one effective tip at a time.

Transitioning seamlessly into the next topic, we now turn our focus to understanding the unique characteristics of Elk Grove Asphalt Pavements.

Understanding Elk Grove Asphalt Pavements

Elk Grove’s asphalt pavements are specially designed to cope with the region’s distinct climate and traffic patterns. To appreciate why regular maintenance is so critical, it’s essential to understand the composition and structure of these pavements. Typically, asphalt is a composite material made primarily of aggregates, binder (bitumen), and filler materials that bind everything together. The quality of these components directly impacts the performance and longevity of the pavement.

Composition and Structure

The foundation of any asphalt pavement lies in its layered structure. The bottom layer generally consists of a robust base that provides structural support. On top of this base, a binder layer is added to ensure durability and flexibility. Finally, the surface layer is laid down, which is engineered to resist wear and tear from constant traffic. Each layer is meticulously designed to distribute the loads from vehicles and minimize damage due to weather changes.

In Elk Grove, the specific blend of aggregates and binders is chosen to optimize performance under both high traffic volumes and varying weather conditions. The bitumen used in these pavements is particularly resilient, formulated to withstand the heat in the summer and the occasional freeze in winter. This resilient design ensures that even as the pavement ages, it can handle minor stresses without significant damage.

Environmental Factors

Environmental influences play a vital role in the performance of asphalt pavements. In Elk Grove, seasonal fluctuations and occasional heavy rains can lead to water infiltration, which gradually weakens the pavement. Moisture combined with the natural expansion and contraction of materials during temperature changes creates an ideal scenario for cracks to form. Additionally, the presence of de-icing chemicals during colder months can further exacerbate the deterioration of the surface.

Traffic load is another critical factor. High vehicle volumes, especially heavy trucks, impose repetitive stress on the pavement. Over time, this stress can lead to rutting, potholes, and surface degradation. The interplay between environmental factors and traffic stresses makes it imperative to employ a maintenance plan that regularly addresses both visible and hidden damages.

Moreover, the urban setting of Elk Grove means that pavements are often exposed to additional challenges such as oil spills and debris accumulation. These factors can accelerate the aging process of asphalt if not promptly cleaned and treated. It’s here that regular inspections become a cornerstone of effective maintenance—spotting minor issues before they develop into significant problems.

In summary, the detailed understanding of the composition and the various external factors affecting Elk Grove Asphalt Pavements lays the groundwork for why meticulous care is necessary. By appreciating the science behind these pavements, managers and maintenance crews can better tailor their repair strategies to the specific needs of the region. As we move forward, the focus will shift toward outlining essential maintenance strategies that build on this foundational knowledge.

Next, we delve into the actionable strategies that will help you keep your pavements in prime condition.

Essential Maintenance Strategies

For long-lasting performance, adopting a proactive maintenance strategy is crucial. In this section, we outline the two main approaches: routine inspections and preventative maintenance. Both strategies play an indispensable role in keeping Elk Grove Asphalt Pavements safe, attractive, and efficient.

Routine Inspections

Routine inspections are the first line of defense in pavement maintenance. Regular assessments help identify potential issues early on, before they evolve into serious, cost-intensive problems. Inspections should be carried out at least bi-annually, with additional checks after extreme weather events. During these inspections, it’s important to look for signs of surface distress such as cracks, potholes, and uneven areas.

A typical inspection checklist might include:

- Visual surveys of the entire pavement surface.

- Detailed evaluation of high-traffic zones.

- Assessment of drainage systems to ensure water isn’t pooling on the surface.

- Documentation of any observed damage for future reference.

- Photographic records to track the progression of wear over time.

By adhering to this routine, maintenance teams can prioritize repairs and schedule interventions that align with the pavement’s actual condition. Moreover, a well-documented inspection process helps in making informed decisions regarding the timing and extent of preventative measures.

Preventative Maintenance

Preventative maintenance goes hand in hand with routine inspections. Rather than waiting for major issues to arise, preventative measures aim to extend the life of the pavement by addressing vulnerabilities as soon as they are detected. This can involve simple fixes like crack sealing, surface cleaning, and applying protective sealants.

Preventative techniques include:

- Crack Sealing: Sealing minor cracks as soon as they appear prevents water from seeping in and causing further deterioration.

- Surface Cleaning: Regular cleaning removes debris, oil, and other contaminants that can compromise the integrity of the asphalt.

- Seal Coating: Applying a protective sealant not only enhances the pavement’s appearance but also provides a barrier against moisture and UV rays.

- Preventative Patching: Addressing small areas of damage before they expand into larger potholes or depressions helps maintain a smooth driving surface.

Integrating these measures into a scheduled maintenance plan reduces the likelihood of extensive repairs later on. Moreover, the initial costs associated with routine upkeep are typically much lower than those incurred from emergency repairs or full-scale resurfacing projects. A detailed preventative maintenance plan might also outline the best times of the year to conduct these activities, taking into account local weather patterns and traffic volumes.

It’s also worth noting that effective communication among the maintenance team is vital. Establishing a system for reporting and tracking issues ensures that all problems are addressed promptly. Modern technologies, such as mobile inspection apps, can aid in streamlining this process by allowing teams to record issues in real time and share updates instantly.

In Elk Grove, where environmental conditions can vary dramatically throughout the year, a comprehensive maintenance strategy is not just an option—it’s a necessity. By combining routine inspections with preventative measures, managers can preserve the structural integrity and appearance of Elk Grove Asphalt Pavements. This integrated approach minimizes the need for costly repairs in the future while also contributing to a safer driving environment.

With these strategies in mind, let’s now explore the advanced repair techniques that can tackle more complex pavement issues.

Advanced Repair Techniques

Even with a robust preventative maintenance plan in place, there will come a time when advanced repair techniques are required. When minor issues have escalated into larger defects, employing cutting-edge repair methods ensures that the pavement is restored to a high standard. This section focuses on two critical areas: crack sealing and patching, as well as resurfacing and rehabilitation.

Crack Sealing and Patching

Cracks are often the first visible sign of wear in Elk Grove Asphalt Pavements. Left unchecked, they can widen over time and allow water and debris to penetrate deeper into the layers. Advanced crack sealing techniques involve cleaning the crack thoroughly and filling it with a specialized sealant designed to flex with the pavement. This flexibility is key, as it accommodates the natural expansion and contraction caused by temperature fluctuations.

Patching, on the other hand, is used when cracks have evolved into potholes or larger voids. The process involves removing the damaged material and replacing it with a hot mix or cold patch material, depending on the severity and weather conditions. Best practices include:

- Thorough Surface Preparation: Remove debris and moisture to ensure optimal adhesion.

- Proper Material Selection: Use patching materials that match the original pavement’s composition.

- Layering Techniques: Apply materials in layers to rebuild the structure gradually, ensuring durability and smoothness.

- Curing Time: Allow sufficient curing time before the repaired area is subjected to traffic.

These repair techniques not only restore the pavement’s integrity but also enhance its overall lifespan. Modern sealants and patching materials are engineered to provide superior resistance against environmental stressors, making them ideal for the variable conditions found in Elk Grove.

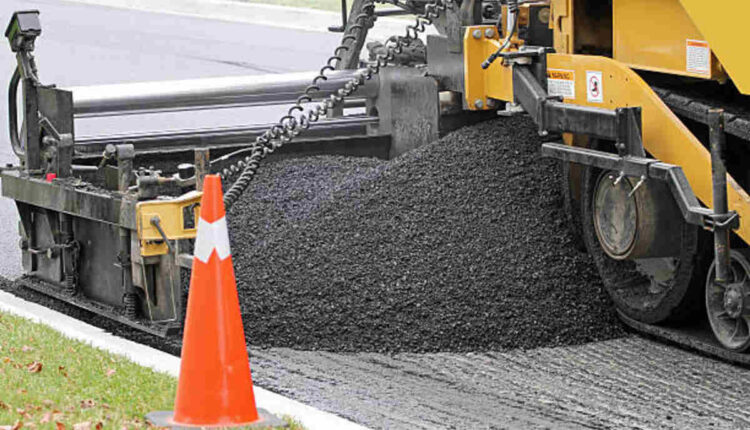

Resurfacing and Rehabilitation

When surface damage becomes extensive, resurfacing might be necessary. Resurfacing involves laying a new layer of asphalt over the existing pavement. This method is both cost-effective and time-efficient, as it avoids the need for complete reconstruction while still addressing surface-level issues. In addition, rehabilitation techniques such as milling—where the top layer is removed before repaving—can be employed to ensure proper bonding between layers.

The resurfacing process typically involves:

- Evaluation: A detailed assessment to determine the extent of deterioration.

- Preparation: Cleaning and repairing the underlying base if necessary.

- Application: Spreading and compacting a new layer of asphalt.

- Quality Control: Ensuring uniform thickness and smoothness across the entire surface.

Resurfacing not only improves the aesthetics of the pavement but also enhances its functional performance by reducing noise, improving skid resistance, and providing a smoother ride. Moreover, these advanced repair techniques can be integrated into a long-term maintenance strategy, ensuring that repairs are conducted before the pavement reaches a point of no return.

Adopting these advanced techniques requires both expertise and the right equipment, which brings us to the next key area of discussion—ensuring that the maintenance team is properly equipped and uses sustainable materials to support these repairs.

Let’s now examine the essential tools and materials that form the backbone of successful asphalt repair projects.

Equipment and Materials

An effective pavement maintenance program relies heavily on using the right equipment and materials. Whether you’re addressing minor surface issues or undertaking major rehabilitation projects, having a well-equipped team can mean the difference between a long-lasting repair and recurring problems. For Elk Grove Asphalt Pavements, choosing high-quality tools and sustainable materials is paramount.

Best Equipment for Asphalt Maintenance

Modern pavement maintenance has benefited from technological advancements. Equipment such as infrared pavement repair machines, crack sealing applicators, and road milling machines play a significant role in achieving precise and durable results. For instance, infrared repair technology allows for quick and efficient heating of asphalt, enabling repairs that blend seamlessly with the existing surface. Other vital equipment includes:

- Asphalt Pavers: For resurfacing projects, these machines ensure a smooth, even application of new asphalt.

- Compaction Rollers: Critical for achieving the required density in new layers and patch repairs.

- Scanning and Inspection Tools: Devices that help in detecting subsurface issues, ensuring that repairs address not only visible cracks but also hidden defects.

Below is a sample table comparing some of the key equipment used in asphalt maintenance:

| Equipment | Purpose | Key Benefit |

| Infrared Repair Machine | Heats and repairs localized pavement areas | Quick, seamless repairs |

| Asphalt Paver | Lays down a new layer of asphalt | Uniform surface application |

| Compaction Roller | Compacts new asphalt layers | Achieves optimal density and durability |

| Crack Sealing Applicator | Applies sealant in cracks | Prevents water infiltration |

| Pavement Scanner | Detects subsurface defects | Enables early intervention |

In addition to these machines, having a well-organized inventory of hand tools such as shovels, brooms, and sprayers is essential for minor repairs and maintenance tasks. Investing in both large-scale equipment and everyday tools ensures that the maintenance team can handle any situation efficiently.

Sustainable Materials

Sustainability is becoming a core focus in infrastructure projects. Modern sustainable materials not only improve the environmental footprint but also enhance the longevity of pavement repairs. For example, recycled asphalt pavement (RAP) has become a popular choice. RAP is produced by reusing existing asphalt material, which reduces the demand for new raw materials and minimizes waste.

Other sustainable options include polymer-modified binders and eco-friendly sealants that are designed to withstand harsh weather while maintaining flexibility. Using these materials ensures that repairs are both durable and environmentally responsible.

For more information on sustainable asphalt practices, you might explore resources provided by organizations such as the Asphalt Pavement Maintenance Association.

By choosing the right equipment and sustainable materials, maintenance teams can ensure that repairs are done right the first time. This approach not only extends the life of Elk Grove Asphalt Pavements but also contributes to lower long-term costs and reduced environmental impact.

Next, we explore the financial side of pavement care—how to plan for and manage the costs associated with maintenance.

Cost and Budgeting Considerations

Budgeting for asphalt maintenance is as critical as the technical repairs themselves. A well-planned budget allows for regular upkeep without causing financial strain. In Elk Grove, where maintenance needs can be both frequent and diverse, it’s important to conduct a thorough cost-benefit analysis and explore potential funding sources.

Cost-Benefit Analysis

Investing in routine maintenance may seem expensive at first, but when you weigh the long-term savings, the benefits become clear. Regular upkeep reduces the likelihood of catastrophic failures that require expensive, large-scale repairs. A detailed cost-benefit analysis should include:

- Initial Costs: Materials, labor, and equipment expenses.

- Long-Term Savings: Reduced need for extensive repairs and resurfacing.

- Indirect Benefits: Improved safety, lower accident rates, and enhanced property values.

Using historical data and performance metrics, maintenance managers can project the return on investment for different types of repair strategies. This analysis helps justify the upfront expense by highlighting the savings realized over the pavement’s lifetime.

Funding and Grants

Many local governments and private entities offer grants and funding programs specifically for infrastructure maintenance. In Elk Grove, tapping into these resources can alleviate some of the financial burdens associated with asphalt repair projects. It’s essential to:

- Research Local Programs: Check with municipal departments for available funding or subsidized maintenance programs.

- Prepare Detailed Proposals: When applying for grants, provide thorough documentation of maintenance needs and projected outcomes.

- Collaborate with Industry Experts: Leveraging partnerships with experienced contractors can enhance the credibility of your proposals.

By carefully planning your budget and exploring diverse funding options, you can ensure that your maintenance program is both robust and sustainable over the long term. Effective budgeting not only covers immediate repair needs but also sets aside resources for future upgrades and emergency interventions.

FAQs

- What are the most common issues affecting Elk Grove Asphalt Pavements?

Answer: Common issues include cracking, potholing, and surface degradation due to weather extremes and heavy traffic. Regular inspections can help identify these issues early. - How often should routine inspections be conducted?

Answer: It is recommended to perform visual inspections at least twice a year, with additional checks after severe weather events or heavy traffic periods. - What is the role of preventative maintenance in pavement care?

Answer: Preventative maintenance, such as crack sealing and seal coating, helps stop minor damages from escalating, thereby extending the pavement’s overall lifespan. - Are sustainable materials more expensive than traditional options?

Answer: While the initial cost might be slightly higher, sustainable materials like recycled asphalt can reduce long-term expenses and have environmental benefits. - Can advanced repair techniques be applied to any asphalt pavement?

Answer: Yes, techniques such as infrared repair and milling followed by resurfacing can be tailored to suit various types of asphalt pavements, including those in Elk Grove. - How can I access funding for asphalt maintenance projects?

Answer: Look into local government grants, infrastructure funding programs, and partnerships with industry experts who can help secure the necessary resources.

Conclusion

Maintaining quality road surfaces is an ongoing process that requires careful planning, regular inspections, and timely repairs. With a thorough understanding of the composition, environmental challenges, and available maintenance strategies, managers can safeguard the integrity of Elk Grove Asphalt Pavements while optimizing long-term budgets. By combining routine and advanced repair techniques with the right equipment and sustainable materials, communities can enjoy safer roads and more cost-effective solutions. The proactive steps outlined in this guide empower you to make informed decisions that benefit both the infrastructure and the environment.

Taking a strategic approach to pavement maintenance not only preserves your investment but also ensures a smoother, safer driving experience for everyone. Remember, the key to longevity is consistent care and a well-planned maintenance schedule.